We have strategically acquired a robust fleet of precision equipment in order to enhance our ability to meet any customer request. Our professional operators and shop personnel have been trained and remain up-to-date on all mechanical processes.

All-American Engineering & Manufacturing, Inc. is ISO 9001:2015 Certified and strives to consistently meet our goals of continual improvement, on-time delivery and defect free products.

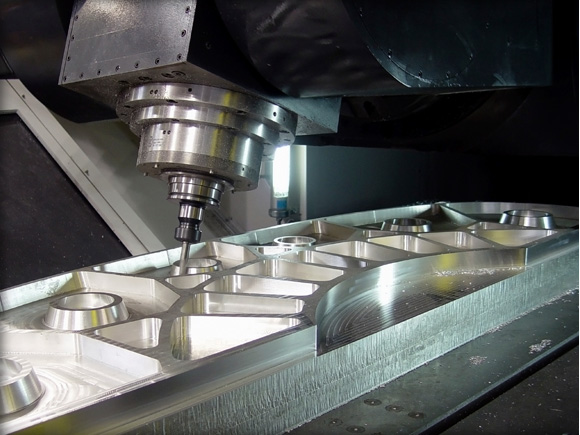

CNC Milling Department

(5) Haas VF-2SS Vertical Machining Centers with Haas controls, Full 4th axis capability, table feed range 30” X x 18” Y x 18” Z

(1) Haas VF-4SS Vertical Machining Center with Haas control, Full 4th axis capability, table feed range 50” X x 26” Y x 25” Z

(1) Haas DM-2 Vertical Machining Centers

(1) Supermax Max 1 Rebel Vertical Machining Center with Fanuc Control, table feed range 30” X x 20” Y x 20” Z

(1) Mitsubishi MV5B Vertical Machining Centers with Fanuc controls, table feed ranges 32” X x 20” Y x 16” Z

(1) NTC TMC40V Vertical Machining Center with Fanuc control, table feed range 30” X x 17” Y x 20” Z

(1) Dyna 4500 Vertical Machining Center with Mitsubishi control, table feed range 20” X x 16” Y x 18” Z

(1) Daewoo ACE V50 Vertical Machining Center with Mitsubishi control, table feed range 40” X x 20” Y x 20” Z, 20 HP spindle.

(1) Haas Model 5C Indexers and Controllers

(4) Haas Model CRT 210 4th Axis

CNC Turning Department

(1) Haas ST-15 Turning center with Haas controls and auto bar feeder

(1) Haas ST-20 Turning center with Haas controls and auto bar feeder

(1) Daewoo Puma 200MC Slant bed Turning Center with Auto-bar automatic bar-feeder and live tooling capability, 2-1/2” through the spindle capacity.

(1) Daewoo Puma 200 Slant bed Turning Center with SMW 4’ bar-feeder.

(1) Daewoo Puma 10HC, Slant bed Turning Center, 10” swing with 30 HP.

(1) Amera-Seiki TC-2 Slant bed Turning Center with 12’ SMW bar-feeder and 1-3/4” through the spindle capacity.

(1) Harding Conquest GT-gang tooling Turning Center with Harmatic bar-feeder

(1) Hwacheon HI-ECO 21H BB Slant bed Turning Center.

Machining Capabilities from a Variety of Materials

Aluminum

Brass

Copper

Bronze

Steel

Stainless Steel

Castable Alloys

High chrome Nickel Alloy

Titanium

Tool Steel

Plastics

Secondary Value-Added Processes

Heat treating

Grinding

Plating

Part Marking

Light Assembly

Sawing Department

(1) DoAll C305 Automatic Cutoff Bandsaw

(1) Kalamazoo H9AW Automatic Cutoff Bandsaw

Stamping Department

(1) 250 Ton Pacific Press former with Coilmatic Feeder, Cooper coil straightener, Cooper double decoiler

(1) 60 Ton Minster Piece Maker with Littell Feeder, Cooper coil straightener, Cooper double decoiler

(1) 60 Ton Bliss 21-1/2 OBI Punch Press

(1) 55 Ton OBI Punch Press

(1) 50 Ton OBI Punch Press

(1) 45 Ton Komatsu OBI Punch Press

(3) 40 Ton OBI Punch Presses

(3) 35 Ton OBI Punch Presses

(2) 10 Ton OBI Punch Presses

(1) Niagara 10 gage, 6’ Shear

(1) 8’ Pacific Press Break, Auto back gage

(1) Westinghouse four post hydraulic press

Manual Machining Department

(1) Millpost Vertical Mill, Variable speed, vise, collets and clamping kit

(1) Sharpe Vertical Mill, Variable speed, Accurite Quick Count II readout

(2) Bridgeport Vertical Mill, Variable speed, Accurite readouts, power feed

(1) Harding TM-UM Horizontal Mill, vise

(5) Drill Presses of various manufacturers

(1) News Indexing collet fixture

(2) Vertical/Horizontal collet fixtures, 5C

(1) Victor TMK 400mm x 750mm Engine Lathe

(1) Rockwell 4 Head gang Drill Press, 12 speeds

(1) Clausing 13” Swing Tool Room Lathe, 48” bed

Stamping – Tool Room

(2) Bridgeport Milling Machine

(1) Van-Norman 22L Horizontal Milling Machine

(1) Boyar Schultz 6” x 12” Surface Grinder

(1) Chevalier FSG-3A1224H Automatic Surface Grinder

(1) Mitsubishi DWC90 Wire Feed EDM

Welding and Brazing Department

(1) Lincoln System 15 Robotic Welding Cell, Fanuc Robot and controls, Lincoln 400 Amp Wire feed welding system and Binzel Torch System

(1) Miller CP200 Wire Feed Welding System

(1) Linde 450 Amp Wire Feed Welding System

(1) 50 KVA Spot Welder with Spot weld Inc Controls

(2) 20 KVA Spot Welder

(1) Oxy Acetylene Torches

* Welding capabilities include:

- Alloy Steel

- Stainless Steel

- Aluminum

Tapping Department

(1) Speedy cut Model ST Precision Tapping Machine

(1) Yuasa Accutap II Precision Tapping Machine

(5) Tapping Heads of various size and manufacture

Abrasive Equipment

(1) Sunnen MBB1600 12 Speed Production Hone with tooling

(3) Kalamazoo 6” x 48” Belt Sanders

(4) Kalamazoo 1” x 42” Belt Sanders

(4) Wissota Double head Bench Grinders

(1) Accu-finish Series II Tool and Cutter sharpener

Finishing Department

(1) Hammond Gemini 4 FB Spiratron Vibratory Finishing System

(1) Tipton US CQ-60 Vibratory Finishing System

(1) Empire Pro-Finish Sand Blasting System

(1) Mr. Deburr 36” x 16” Vibratory Finishing System Yale Ultra-Sonic Parts Cleaning System

(1) Burr Bench 4616 Vibratory Finishing System

(1) Almco SR2 Vibratory Finishing Systems

Inspection Department

(1) Brown & Sharpe Global Performance Coordinate Measuring Machine, Tesa Star Indexing Probe Head, Renishaw Probe, PCDmis CAD + Software and related computer equipment

(1) Numerex 12” x 18” Manual CMM with Numerex software and related computer equipment

(1) 48” x 72” Grade A Gray Surface Plate (Rock of Ages)

(2) Wilson Rockwell Hardness Testers (1= Standard Scale, 1= Superficial)

(1) Sherr-Tumico 30” Horizontal Optical Comparitor with Quadra Chek measuring system, background and Surface Illumination and power feed in all axis

(2) Gage Master Finite 20 Optical Comparitors with Readouts

(3) Brown & Sharpe Tesa Hite Digital measuring gages

(3) Sunnen Precision Bore Gages, Model PG800 with setting gages

(1) Meyer Pin gage set, .011ӯ to 1.240 ӯ

(1) Brown & Sharpe 587 Height Gage with Indicator

(1) Baush & Lomb Optical Inspection System

(1) Mititoyo Surf test 402 Surface Analyzer Profilometer

(1) Mitutoyo Grade 2 Metric Gage Block Set

(1) Mititoyo Borematic Bore Gages, .375ӯ to 4.200ӯ

(1) 5” x 5” Magnetic Sine Plate

(1) 5” x 10” Sine Plate

(1) Cadillac Height Gages with 6” risers

(1) Various Federal Snap Gages

(1) Various Thread Plug Gages 0-80 to 1-1/4-7

(1) Various Thread Ring Gages

(1) 24” x 36” Trustone Grade A Surface Plate

(1) 18” x 24” Grade A Surface Plate

(1) Gage Block Set for calibration use only

(5) Gage Block Sets for daily use

(1) Full complement of pin gages

(1) Full complement of thread ring gages, non-typical sizes

(1) Cabinet, ID, OD and special measuring tools of various size and manufacture

Support Equipment

(1) Ingersoll Rand IRN30H, Nirvana Variable Speed Air Compressor System

(1) Gardner Denver 25 HP Rotary Air Compressor

(1) Refrigerated Dryer System

(1) Clark C25 5000# Capacity Forklift

(1) Various material handling equipment

(1) Pemserter Fastener Insertion system

(1) Taumel Assembly Systems Rivet Setter

Support Software

(1) Job Boss ERP Software system with associated computers and networking equipment.

(1) Gibbs cam CAD/CAM system

(1) Auto Cad